"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

04/20/2016 at 17:30 ē Filed to: racnerho

5

5

10

10

"RamblinRover Luxury-Yacht" (ramblininexile)

"RamblinRover Luxury-Yacht" (ramblininexile)

04/20/2016 at 17:30 ē Filed to: racnerho |  5 5

|  10 10 |

Because of reasons, I have a Ford Ranger transfer case mounted in my project to do PTO things with. This has resulted in one point of trickiness - how do you get a transmission-mounted case turned into a standalone unit?

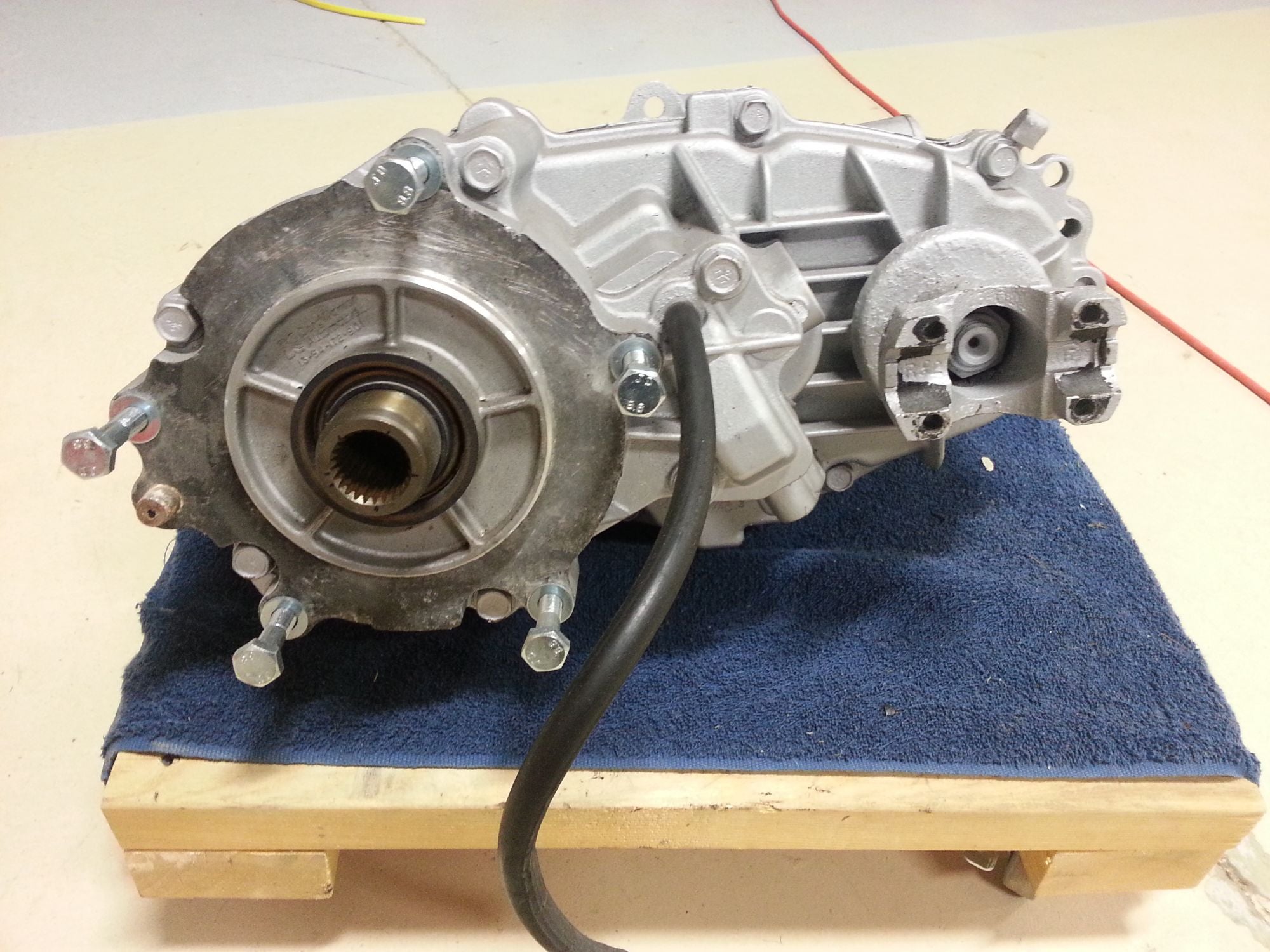

The electric version Borg Warner 1354 transfer case: tough, light (<55lb when you ditch the low-range planetary and the harmonic damper), works well in either direction and most orientations if handled properly (displacement circulating pump, chain drive with no tensioner), and has electric drive which can also be converted to manual, as it just moves the internal selector with a screw. It has one integral 1310 U-joint yoke, and a standard Ford size plate on the other output. However, there is a spline on the input, a spline that must be matched to make a slip-yoke.

Happily, output shafts for an automatic 4r44E are pretty cheap, in the $30 range. However, these shafts are hardened to a very high degree. How do you make something attach to that?

Typically, youíd be working with something like the below: a Spicer PTO yoke, available keyed or unkeyed for press fit.

Obviously, if you could install a keyway in the shaft or weld on the yoke, it would be ideal. Letís discount a press fit for now, because the shaft diameter is a couple thousandths of an inch loose, and would never transmit sufficient torque. So, after youíve cut the end off the Ranger output shaft with a suitable abrasive wheel, youíd want to set up for welding or cutting a keyway. Thatís where some trouble sets in.

Welding is all well and good, but weíre talking trying to weld high carbon treated steel to malleable iron. Not good at the best of times, and requires the whole thing to be heated up while welding, welded with more power than I have available, cooled, and re-heat treated. Then it would need to be balanced, and even then it might (would) develop cracks. On the other hand, cutting high carbon tool-hard steel, and accurately, is difficult even with a carbide bit, and itís way harder if you donít have a mill. Okay, send it to a machine shop... and maybe get it right? Worse, even if you get the keyway right, there are some issues that present from using a keyway in pre-hardened steel, and some upper limits on torque. Not so good.

Enter... magic:

As it turns out, Loctite 660, which is designed for filling gaps in things that are supposed to be press fit and arenít, is absolutely positively ideal for this. The existing several thousandths loose slip fit is perfect, because this stuff will fill up to a .020" gap. But wait, you say - how can it possibly be strong enough? Well, as it turns out, the shear strength of 660 is upward of 3300psi. That ends up in this application translating to well over a thousand ft-lb of torque. If it breaks loose despite that, it will slip safely in place rather that fracture. If I need to disassemble, I just have to heat it significantly (~500F), and it breaks down.

So there you have it - the story of how I decided to just glue something together.

Clown Shoe Pilot

> RamblinRover Luxury-Yacht

Clown Shoe Pilot

> RamblinRover Luxury-Yacht

04/20/2016 at 18:12 |

|

Well engineered adhesives are indeed wonderful magical things.

uofime-2

> RamblinRover Luxury-Yacht

uofime-2

> RamblinRover Luxury-Yacht

04/21/2016 at 11:23 |

|

I was going suggesting trying to broach the key way using a form tool on a lathe, like this:

you might have to anneal the end of shaft first if itís to hard to cut

RamblinRover Luxury-Yacht

> uofime-2

RamblinRover Luxury-Yacht

> uofime-2

04/21/2016 at 11:37 |

|

While that is a good idea, it would require me to get a whole bunch of accessories for the lathe I do not have, and/or take it to a machine shop and face the same issues with hardness and re-heat treating vs. embrittlement and overworking the surface as is as doing multiple passes with a mill. It also still leaves me with (perversely) a 1 1/8" keyed shaft which isnít theoretically quite rated for enough torque. Use of a keyway limits me to less than 10% of the shear area that a press/surface contact has, with a lot of stress concentrators. Reference guidelines actually say ďnoĒ on a keyed shaft, so if I were doing it Iíd be in excess of recommendation.

So, while in theory a press fit for some things is inferior, an enhanced simulated press fit on a longer sleeve... isnít.

If I had stock to weld a much larger piece to a larger diameter yoke, the ability to cut new splines, and then heat treat a whole *new* assembly, it would be perfect, that or machine the whole thing from scratch, but I donít have the wherewithal, and I donít want to let the perfect be the enemy of the very good.

uofime-2

> RamblinRover Luxury-Yacht

uofime-2

> RamblinRover Luxury-Yacht

04/21/2016 at 11:49 |

|

While not exactly the same, back in school I did a lot of work bonding aluminum threaded inserts into carbon fiber tubes. I machined the inserts to have the nice bond gap line you have ~.020", prepped the surfaces as recommended, did all the bonds carefully, followed the proper cure cycles and in the end a whole bunch of the inserts came un bonded despite the fact that they theoretically could hold a couple thousand pounds and at most never should have seen more than a hundred or so. Admittedly there was a ton of vibration which Iím sure didnít help matters

Be really careful when you do the bonding the biggest cause of failure as far as I could determine was that it is very easy to get air traps in your bond area and those cause stress concentrations which become failure points.

Our solution was drilling holes in the outer tube and injecting the resin through those to try to clear all the air out while filling (It worked somewhat better)

uofime-2

> RamblinRover Luxury-Yacht

uofime-2

> RamblinRover Luxury-Yacht

04/21/2016 at 11:51 |

|

This PTO is for your jet (?) drive right? So what is the actual maximum torque that will produce, thatís actually probably a hard question to answer. Either way at the very least that should prevent excessive shock loads.

RamblinRover Luxury-Yacht

> uofime-2

RamblinRover Luxury-Yacht

> uofime-2

04/21/2016 at 12:17 |

|

Unfortunately, the setup of things means that output needs to face the rear axle. So, some shock and vibration are in play. As to maximum torque, if it ever exceeds 700 ft-lb, I have much more serious problems happening, like trashing the transmission. The engine can probably throw upward of 230 ft-lb, and the transmission has a ~4:1 first gear ratio, but I dare not ever let the twain meet, because the trans is not rated for that much in first gear. Richmond Gear, current producer of Super T-10s, rates them for a max torque by 1st gear rating on the cluster, and while they donít offer one as low as GM offered, you can calculate that the trans shouldnít see more than 175 or so in first from their numbers for other first ratio setups. So, I shouldnít try to run all the way up to 50-60 in first, probably.

As far as air gaps, theyíre probably less of a problem from the stress concentration viewpoint here than the anaerobic one - Loctite 660 only cures in the absence of air, so air pockets can seriously mess up hardness and cure time. Fortunately itís designed to be slimy in just such a way as to make bubble reduction very easy. Thick, but not much in the way of consistent viscosity. Less like a resin, more like ketchup.

At the end of the day, a lot of the issues with key use - fit, fineness of machining, load rating, stress concentrations, etc. can be defused somewhat by bedding a key in 660. As long as I get a keyway shaped within .020, I should be able to use a key as backup and a means of diffusing shock loads, without the keyway having to be perfect or having to take the load, the full load, and nothing but the load. So, my best option may actually be to cut a keyway with an abrasive wheel and filing, and then assemble with 660 *and* a key, with the 660 making up for some of the keyway methodís deficiencies.

uofime-2

> RamblinRover Luxury-Yacht

uofime-2

> RamblinRover Luxury-Yacht

04/21/2016 at 14:57 |

|

I never thought about trying to cut a keyway with a grinder, with come clever fixturing you probably could hold .020". I know Iíd feel a lot better having both.

For some reason I thought you had a lathe, just mount the parting tool sideways and you have the perfect form tool for a keyway as long as you can lock the chuck in one position. But if you donít own one most people probably wouldnít like you doing hood rat shit with theirs...

RamblinRover Luxury-Yacht

> uofime-2

RamblinRover Luxury-Yacht

> uofime-2

04/21/2016 at 15:04 |

|

Definitely. I could do with *only* 660, even if risking a failure because a failure is essentially meaningless. ďoh, no, I have to disassemble and recoatĒ. A key failure that could damage the keyway from me having gotten off by .010 or just from too much power... no thanks. Both - probably best across the board. Thereís a pretty nice lathe in my dadís shop, but it is missing tools and doesnít yet have a three phase box to run, so I havenít been leaning on it.

uofime-2

> RamblinRover Luxury-Yacht

uofime-2

> RamblinRover Luxury-Yacht

04/21/2016 at 15:18 |

|

well.... for this hood rat shit you donít want it to run so thatís not actually a problem. The lack of tools, or more critically tool holders is.

RamblinRover Luxury-Yacht

> uofime-2

RamblinRover Luxury-Yacht

> uofime-2

04/21/2016 at 15:25 |

|

I did a lot of reading up on the specific issue of cutting keyways into a hardened workpiece with a mill, and the end gist is that it *can* be done, but it requires a super-thin chip, insane pressure, no oil (!), really good bits, oh - and it work-hardens the everloving fuck out of the surface. So, yeah. Hood rat shit in its own right. Remove the need to be super precise and itís much better because you can do stupid things like a 4" grinder in a jig.